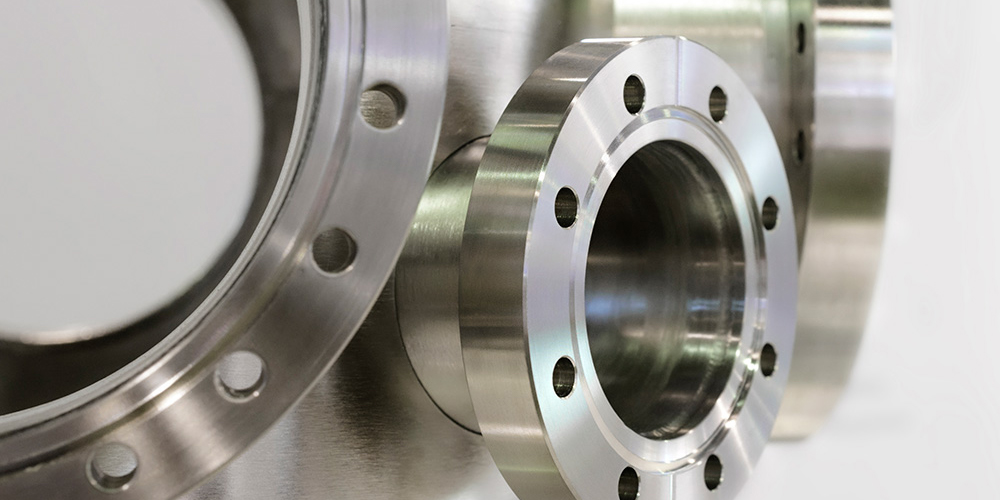

What Is Surface Finish and Why Is It Important?

A surface finish is an important part of many manufacturing projects. It allows the product to be functional, and improves the look and feel of the product. During the process, the surfaces are usually left alone and won’t go through any further processing. By understanding the different types of surface finishes, you can ensure the best quality for your project, reduce your trial and error process, and ensure the best possible results. Read on to learn more about these treatments.

A surface treament finish is a process used to enhance the appearance, performance, and appearance of manufactured items. A good surface finish is crucial for a number of reasons. Not only does it make the product easier to work with, it also increases its lifespan. If you’re looking for a new metal surface, consider the many benefits of surface finishing. A high-quality finish will improve the aesthetics of the finished product. If you want to get the best possible results from your metal parts, it’s important to get the right surface treatment.

A surface finish is a type of material that protects the underlying product surface. The final goal of the treatment is to improve the overall appearance of the product. The process can be applied in several ways, varying the thickness and color of the material. Depending on the application method, surface finish can be applied to the entire product. In some cases, the application will be only one step in the manufacturing process. This will allow the manufacturer to focus on other aspects of the product.

In general, there are three major types of surface finishing processes: organic, metallic, and miscellaneous. The most common of these is bead blasting. It can be used for aesthetic purposes, or can serve a variety of functions, including improving cleanability, tribology, and corrosion resistance. The choice of media is key to achieving the desired texture pattern and operating conditions. When choosing the right surface finish for your project, you should consider how to make the most of it.

Pickling is a popular method used to remove impurities and irregularities from metal surfaces. A pickling process requires an acidic substance that acts as an additive to prevent corrosion. It is also used to increase the aesthetic value of the product. It can make a component more attractive and more durable. The process is easy to apply, and it is a good way to improve the appearance of the product. It is also a great way to enhance the overall value of your product.

When it comes to the different types of surface finishes, it’s useful to compare them with the roughness parameter of the product. Ra is a measure of the arithmetical mean deviation of a surface. The lower the number, the smoother the result. However, it’s important to remember that a smoother surface isn’t always better. It’s important to consider the use of the products you choose.

Choosing the right surface finish is a complex process. It may seem simple enough, but the benefits of these treatments depend on the final use of the product.